Innovation and efficiency: CMS Additive Manufacturing solutions

CMS is a company that from 1969 has stood out in the field of design and production of advanced machines and systems for fabricating with a variety of complex materials: composites, carbon fibers, aluminum, light alloys, plastics, glass, stone and metals.

Its strategic vision is to offer customized, cutting-edge solutions. For this reason, CMS has always focused on in-depth knowledge of processes in order to offer companies a long-term competitive advantage.

Continuous innovation and investment in research and development have allowed CMS to maintain a leading position in all its sectors.

The 5 Business Units in CMS

CMS is divided into five specialist brands: CMS Advanced Materials technology, CMS Plastic technology, CMS Stone technology, CMS Glass technology and CMS metal technology. These are business units that offer excellent solutions in extremely demanding sectors such as aerospace, automotive, marine, transport, eyewear, industrial, wind turbine production, construction, architecture, interior design and urban furniture.

Each business unit focuses on a specific area, providing machines capable of meeting the different needs in various application areas.

CMS Advanced Materials

The Advanced Materials Technology Business Unit has established itself as a benchmark in design and construction of numerically controlled machining centers for advanced materials, composites and metals.

In particular, it has developed machines that are best-in-class for their precision, speed and reliability, confirming it as a technological partner in the aerospace, automotive, industrial and transport sectors

CMS Additive Manufacturing solutions

In 2018, CMS Advanced Materials Technology launched an ambitious investment in research and development, with the aim of integrating a Large Format Additive Manufacturing (LFAM) solution into its range of machines. This innovation was designed to revolutionize the industry by optimizing use of composite materials and opening up new prospects in terms of efficiency and sustainability.

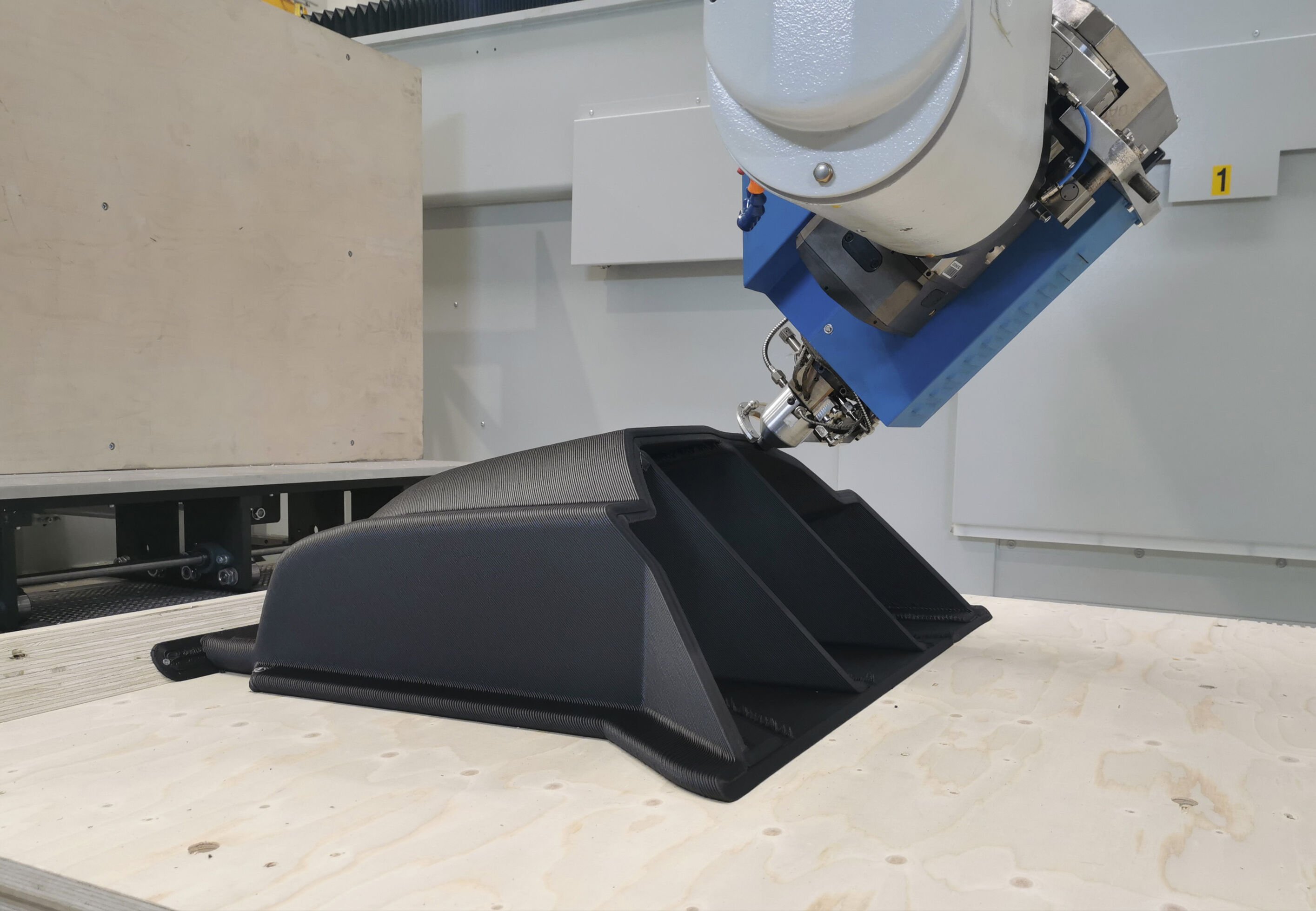

The idea behind developing this range is to leverage advanced materials, such as thermoplastic polymers and fiber-reinforced composites, to produce large format structures with high strength and precision. With LFAM (Large Format Additive Manufacturing) technology, extrusion systems can be used with thermoplastic polymers in the form of granules, either unreinforced (100% polymer) or, more frequently, filled with carbon or glass fibers. In many cases, they are combined with hybrid techniques that integrate subtractive processes to improve surface finish and dimensional tolerances.

Typical applications for this innovation range from production of semi-finished products to final components, while offering greater flexibility and reducing material waste. The technological outcome of this journey can be seen in a full range of cutting-edge machines, designed to meet multiple needs in the field of additive manufacturing.

CMS Kreator

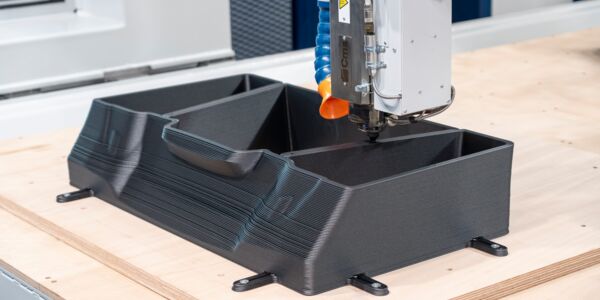

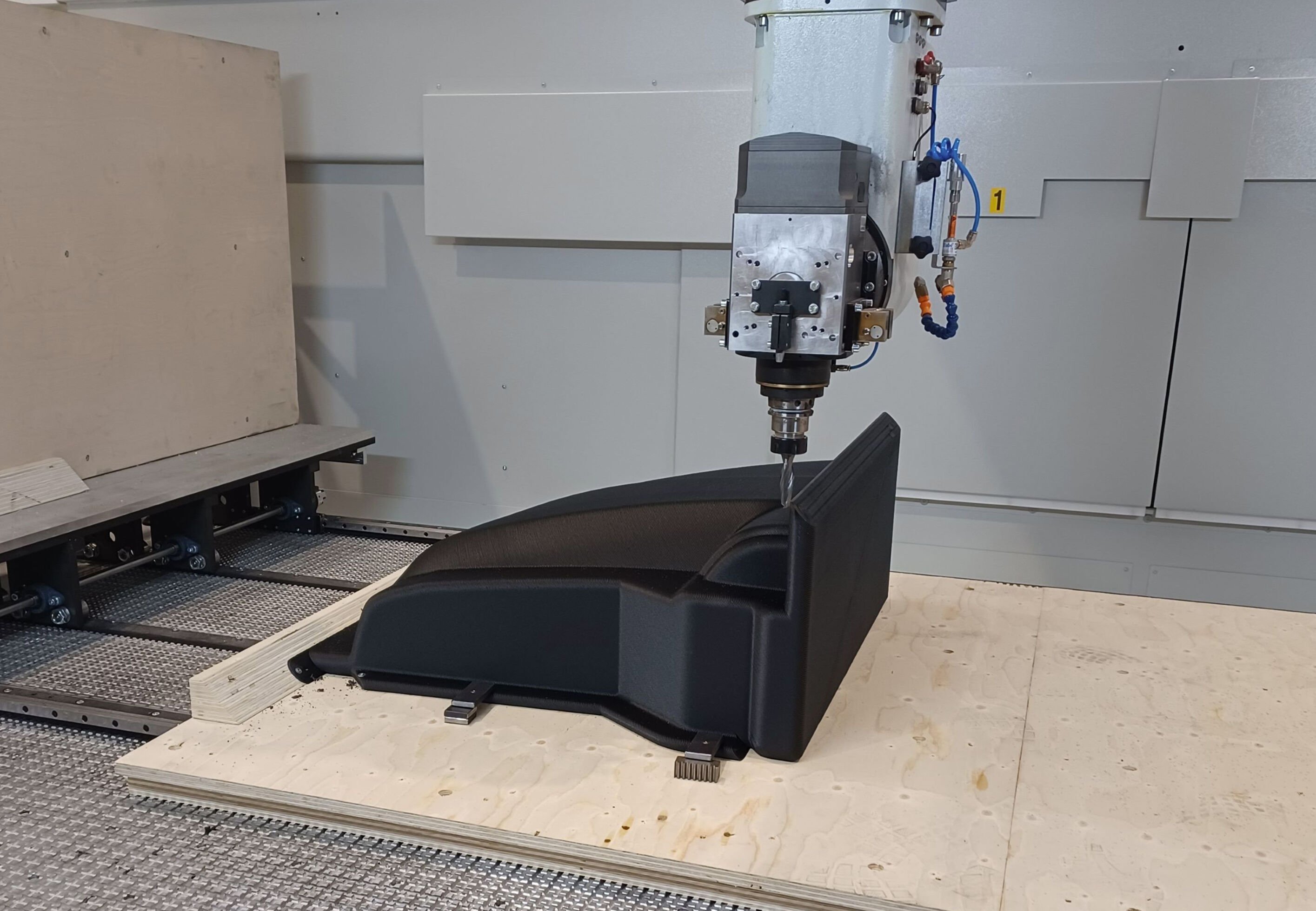

CMS Kreator is a hybrid system that combines additive manufacturing with milling technologies. This machine unites the power of 3D printing for large formats with the precision of milling to ensure unprecedented results in a range of production processes

CMS Kreator embodies CMS's expertise in designing and manufacturing CNC machines, leveraging over 50 years of development in this sector. This machine is capable of working with a wide range of materials, including thermoplastic granules, glass or carbon fiber, composites, aluminum, light alloys and metals.

The CMS LFAM solution is the ideal solution for fabricating composite tooling, rolling dies and assembly jigs, with particularly advantageous applications in the motorsport, defense and transportation sectors. Able to operate at printing speeds up to 16 meters per minute, it is designed to meet the need for high precision and productivity.

CMS Kreator can print at 0°, 45° and 90°, offering great flexibility to adapt to the types and characteristics of the workpieces to be produced.

CMS Kreator A3

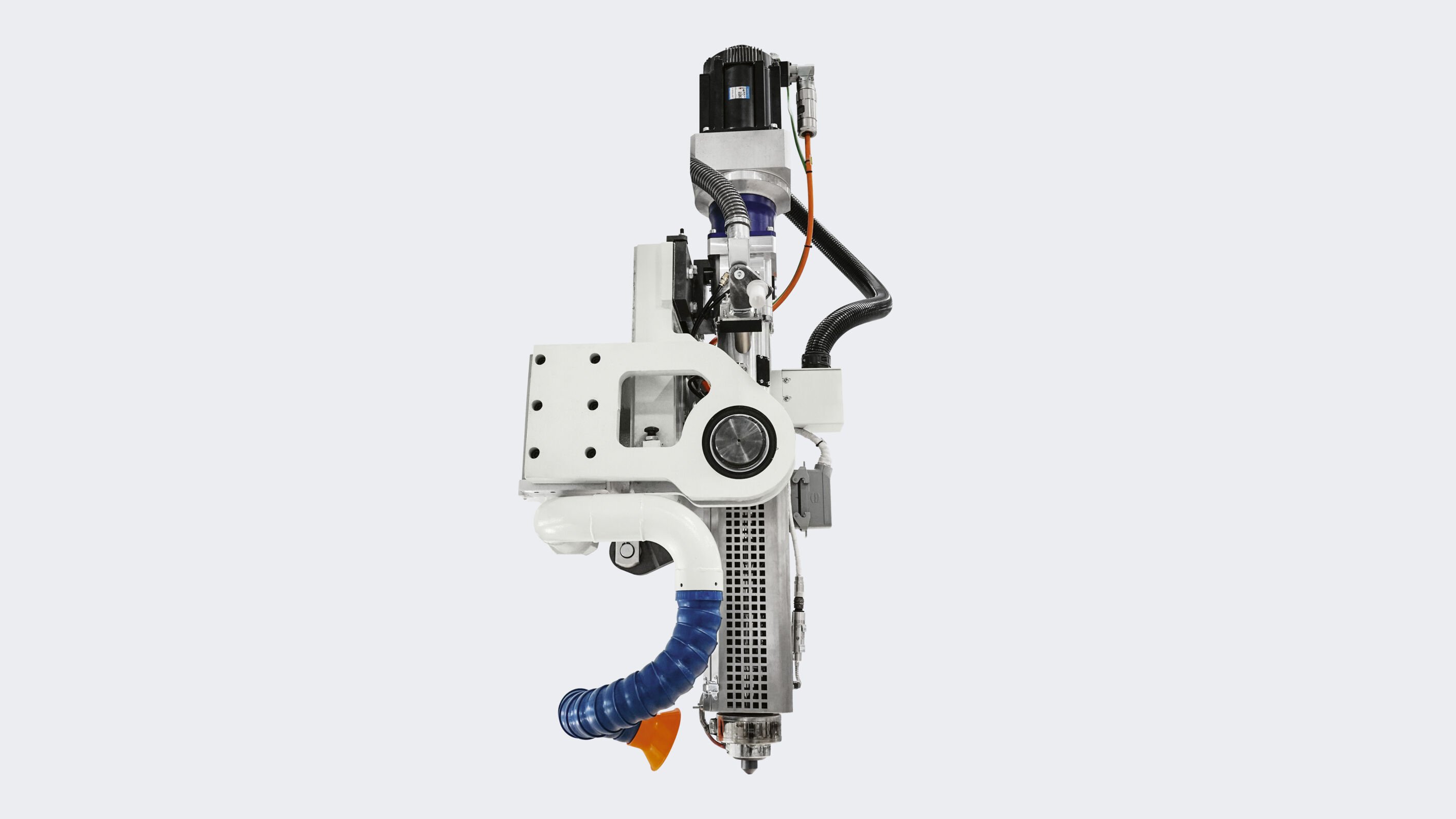

The new CMS Kreator A3 model is an example of evolution in large format 3D printing. It integrates innovative technologies to meet the needs of the industry through additive manufacturing.

The machine exploits a screw extruder with a maximum capacity of 30 kg/h, designed to work with thermoplastic polymers.

With its innovative extruder tilting device, CMS Kreator A3 offers the flexibility to pass from printing vertically to printing at a 45° tilt and horizontally. This feature guaranteesextraordinary design flexibility, without compromising the precision and efficiency of the production processes.

From a technical perspective, the machine works on an X axis that can vary from 2,500 to 9,800 mm, a Y axis of 2,500 mm, and a Z axis of 1,300 mm. The maximum fabrication temperature reaches 450°C, with nozzles that range from 10 to 15 mm in diameter, allowing a remarkable printing speed. It is compatible with a wide variety of materials, including PLA, PETG, ABS, PA6, PC, PEI and other fiber-reinforced materials, ensuring the versatility needed for numerous industrial applications.

The benefits of choosing CMS technological solutions

The range of CMS machines designed and built for the Large Format Additive Manufacturing sector offers numerous benefits, including:

Timing

CMS solutions can produce dies and other tooling in much faster times than with traditional production methods.

High flexibility

Patented technological systems mean that CMS solutions offer extraordinary production flexibility, making it possible to adapt production to the specific needs of every customer. The option of using a variety of materials and different printing configurations makes CMS machines ideal for numerous applications.

Material savings

CMS allows significant material savings to reduce costs and environmental impact, with considerably lower weights than the same tooling types fabricated with traditional systems. This makes CMS technology particularly attractive for companies looking to optimize production processes and reduce waste.

Sustainable solutions

CMS machines are designed to reduce greenhouse gas emissions by 60% compared to traditional methods. This commitment to sustainability is fundamental for companies aiming to reduce their environmental impact and comply with modern production standards.

Material procurement

Today, since thermoplastic granules are more readily available than aluminum or polyurethane resins, companies can benefit from an additional competitive advantage by simplifying procurement of the materials needed for production.

End of life of dies and recycling

Carbon or resin tooling is complex to dispose of (it is mostly buried or burned in special furnaces), while thermoplastic resins are partially or totally recyclable. Dies made with 3D technology can be reground or regranulated at the end of their life so that they can be used for new applications. Regranulated parts can also be mixed with virgin material, depending on the performance required of the die to be fabricated.

Software package

CMS is the only company able to offer a complete package of slicing hardware and software. The exclusive patented Icarus software was developed to be very user-friendly, and to ensure simplified, efficient process management, i.e. temperature management, printing time reduction and production workflow optimization.

It should also not be forgotten that CMS has an in-house Additive Manufacturing team that can continuously provide customers with a complete service.

Conclusions

CMS Advanced Materials offers cutting-edge solutions with machines that combine innovation, flexibility and sustainability. This all serves to meet the challenges of modern companies and contribute to efficient and environmentally friendly growth.