CMS and Knaus Tabbert: thirty years of excellence and innovation

advanced material

CMS and Knaus Tabbert: thirty years of excellence and innovation

We are in Germany, and more precisely in Jandelsbrunn, Lower Bavaria, at Knaus Tabbert, a European leader in recreational vehicle manufacturing that specializes in designing and building camper vans, caravans and motorhomes.

The group owns several brands, including KNAUS, TABBERT, WEINSBERG, T@B and MORELO to offer vehicles that suit every need and price range, from the entry-level compact segment to luxury models.

We meet Ewald Bauer, vehicle and bodywork production and fabrication manager, who accompanies us on a visit to the company's various production departments.

“We chose CMS”, says Bauer, “because its machines have very solid structures and very high execution accuracy”, and it is precisely because of these fundamental characteristics that the collaboration between Knaus and CMS has lasted for over thirty years. Knaus has integrated a total of 13 CMS machines into its production over the years.

Every new purchase was a step forward in the production capacity of Knaus, from the first machines for vehicle and camper van side panels, which were capable of machining complex geometries on large workpieces, to modern CNC solutions with automatic loading. Later, the first automated nesting machine was introduced in 2001, paving the way for an increasingly customized and efficient production process.

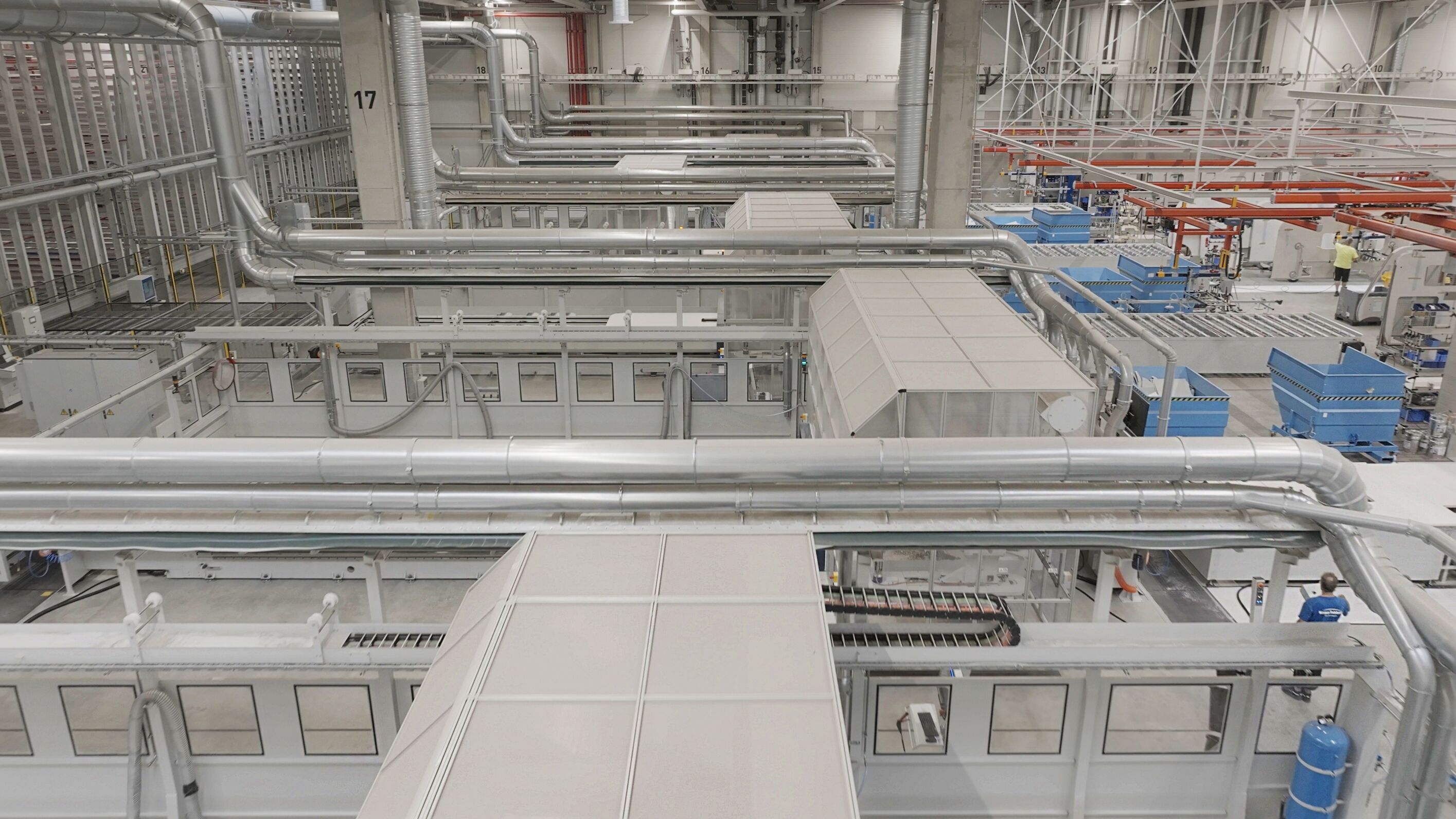

A few years ago, Knaus completely renewed its production department and installed five new CMS avant caravan machining centers to quickly and efficiently produce walls, roofs and floor elements for its vehicles.

The choice of CMS as a technical partner was motivated not only by the reliability and precision of the solutions, but also by the quality of the support provided. “We can count on a knowledgeable contact person”, says Bauer, “in fact, with CMS Germany we enjoy an excellent service.”

CMS technological solutions are well integrated into the Knaus production chain and work without interruption, creating the elements that will make up the wide range of products that the company offers its customers, one after another.

“We are pleased to have been able to meet our customer’s requests”, says Matteo Radicioni, CEO of CMS, “and we are sure that our machines will contribute to the success of Knaus.”

CMS & Knaus Tabbert

Fill out the online form to be contacted by a salesperson