Scopri il modulo GIS: la nuova orbita del taglio ibrido lama/coltello

17/apr/2025In an increasingly demanding market, where flexibility and processing speedmake the difference, it is essential to adopt technologies that optimizeproduction processes. With the GIS module, CMS introduces a new solution for blade/knifecutting, overcoming the limitations imposed by tools controlled viaelectrospindles and offering a new dimension in the world of integrated units.

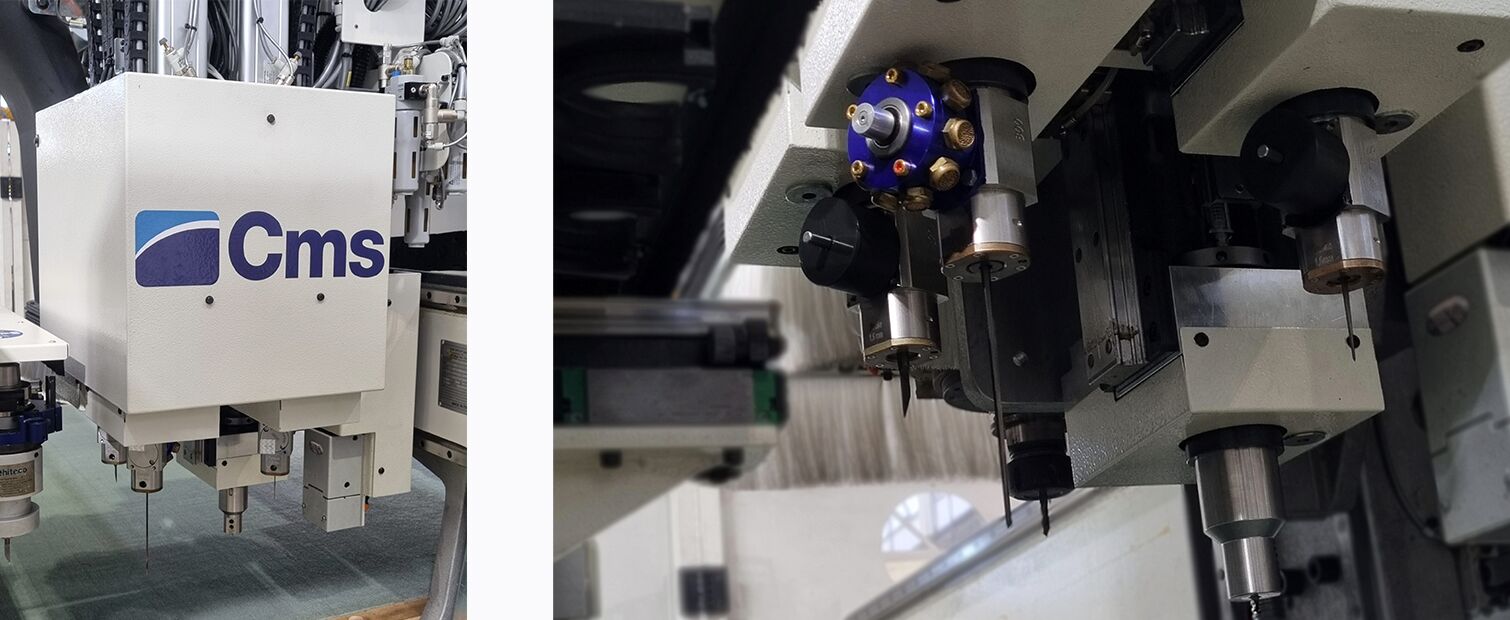

With the GIS module, CMS introduces a new solution for blade/knife cutting, overcoming the limitations imposed by tools controlled via electrospindles and offering a new dimension in the world of integrated units.GIS is an independent module, specifically designed for blade/knife cutting,working synergistically alongside the machine’s main electrospindle. It allowsthe full potential of both heads to be exploited without interruptions or toolchanges, optimizing production times and increasing operationalefficiency.

The GIS unit is available in three configurations to suit every production need:

• GIS 1 one tool available on the machine

• GIS 2 two tools available on the machine

• GIS 4 up to four tools available on the machine

All versions are equipped with independently insertable carriages that allow for a quick switch of cutting technologies and exceptional operational versatility.

The GIS module ensures precise machining on a wide range of materials such as expanded PVC, elastomers, honeycomb polycarbonate, and foam, offering maximum versatility thanks to its plug & play technology, which makes tool changes quick and intuitive.

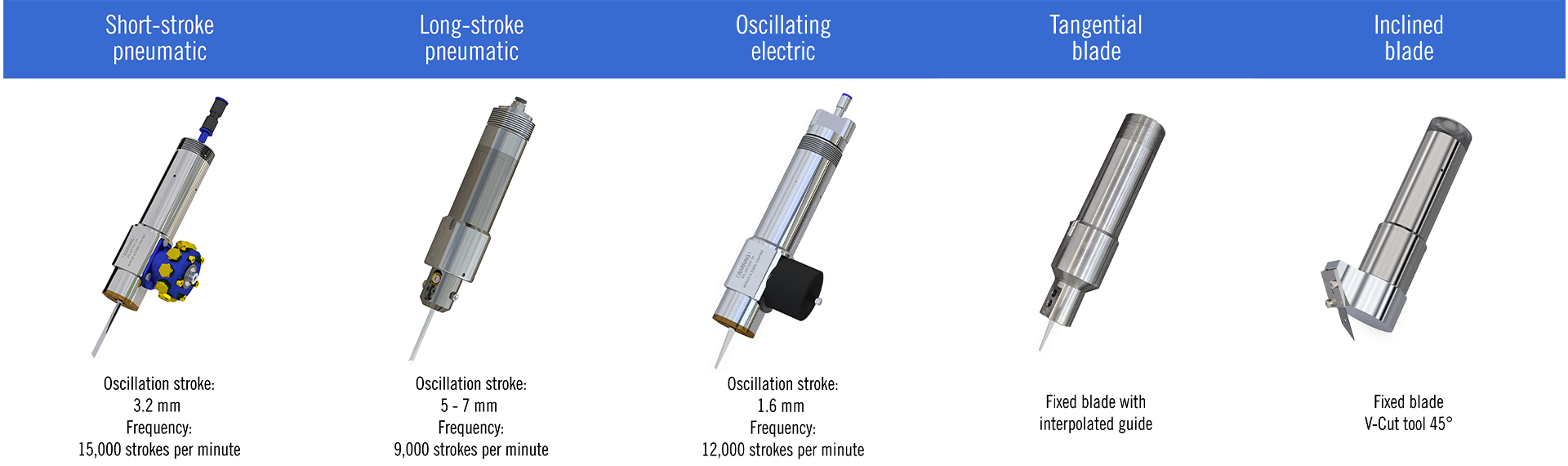

CMS offers five types of tools:

And that’s not all!

Upon request, additional tools can be integrated to expand the machine’s capabilities. Our experts will help you identify the most suitable solution to optimize your processing workflow!

GIS includes the Overcut Compensation function by Maestro, which optimizes the cutting path to eliminate defects such as the “sawtooth” effect and overcutting. The result? Clean, precise, and flawless cuts.

Additionally, the module integrates perfectly with the “Optiscout” optical marker management system, allowing maximum machine efficiency—especially in sign making, visual communication, and digital cutting applications.

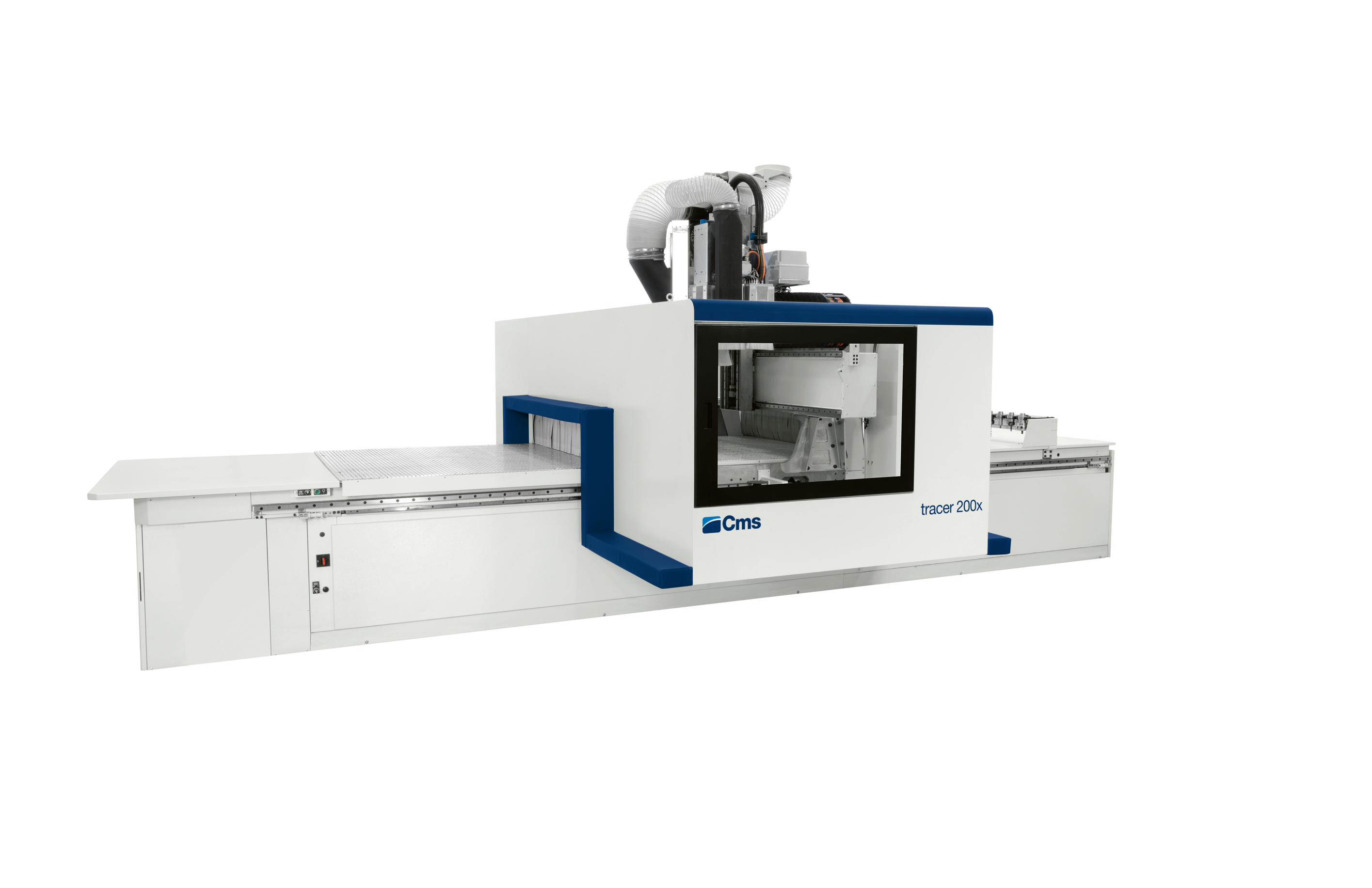

GIS and tracer 200x: the perfect integration

The GIS module reaches its highest potential in the CMS tracer 200x range, designed to seamlessly combine milling and blade/knife cutting.

Thanks to its compact structure and Pro-Speed and Pro-Space protections, the tracer 200X offers:

• Worktables up to 4317 mm x 2177 mm, with the option to operate in pendulum mode to alternate milling and cutting

• 40,000 rpm electrospindle for ultra-high-quality finishes

• Simplified programming and interactive management of tools and clamping systems

Discover how GIS can transform your production process! Contact CMS experts for more information.