ARS TECH and CMS: maximum precision meets carbon fiber

advanced material

ARS TECH and CMS: maximum precision meets carbon fiber

We are in Controguerra, a small town in the province of Teramo, in the heart of the Abruzzo region in Italy, where ARS TECH is based, a company that, in just a few years, has established itself as a leader in the production of carbon fiber structural components in the motorsport and hypercar sectors.

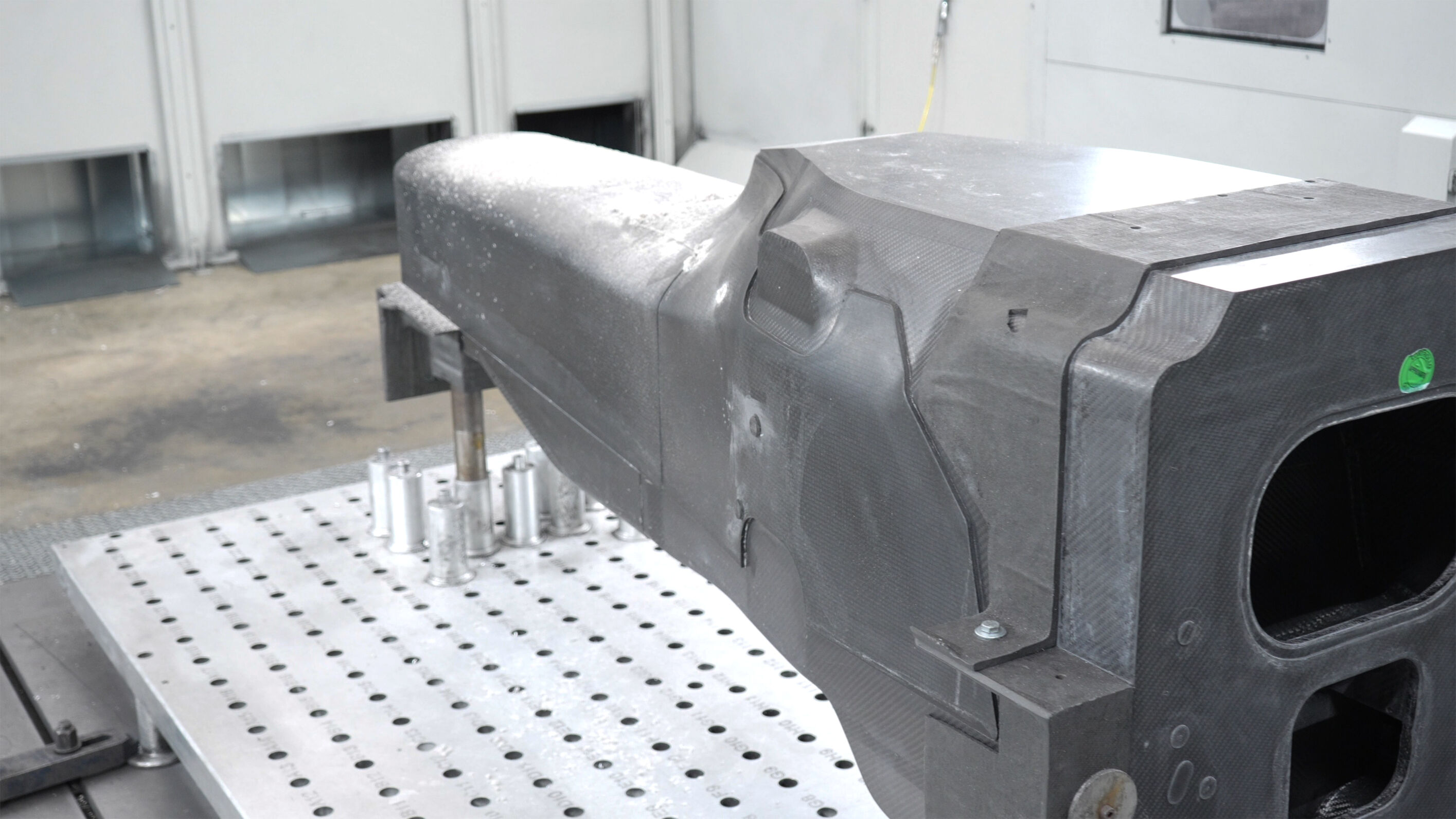

With a completely in-house production and thanks to the 25 CMS numerical control machines, ARS TECH combines innovation, quality and precision, distinguishing itself for unique solutions such as monocoque frames without gluing tips or joints, Used today in the most prestigious motor racing. Just think of Formula 2,3 and 4 and the legendary 24 hours of Le Mans, where 63% of the vehicles on track are equipped with ARS TECH components.

A strong and long-lasting bond with CMS, which accompanies ARS TECH from the beginning. Today, each department of ARS TECH has several CMS numerical control machines covering a wide range of technologies: from milling to drilling, from ultrasonic cutting to waterjet cutting systems.

Thanks to machines such as antares k, tecnocut proline, mx3, mx5 and ethos, the company is able to respond to the most challenging needs, ensuring complex cuts, centesimal finishes and exceptional strength for notoriously difficult to work materials such as carbon fiber.

“Drilling a frame made of carbon fiber is extremely complicated, it is a very hard and resistant material. The robustness of the CMS ethos machine guarantees us quality aspects at centesimal levels.” explains Carlo Balucani, CEO of ARS TECH.

The adoption of advanced digital technologies such as CMS Active and CMS Connect allows ARS TECH to constantly monitor and optimize their production processes, improving the efficiency and quality of the final product.

In a constantly evolving sector, ARS TECH confirms itself as an excellence ready to lead the automotive industry into the future, with the technological support of CMS, “a fundamental partner that guarantees the company the possibility of having a high, fast and safe production rate.”

CMS & ARS TECH

Fill out the online form to be contacted by a salesperson